Automotive

Thermal Management Solutions

At Armstrong, we understand the importance of effective thermal management in a vehicle. With a deep understanding of the principles and techniques involved, we are able to offer our customers tailored solutions that meet their unique requirements.

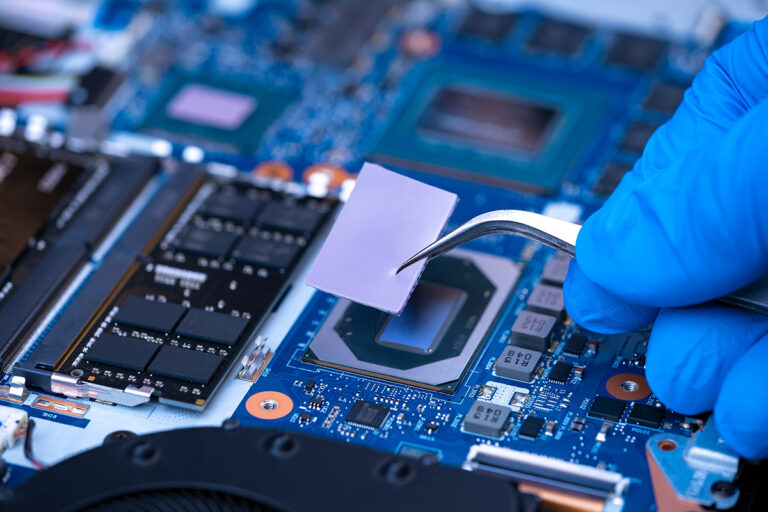

Vehicle Electronics

Thermal gap interface for electronic circuits & components

Requirements

- To dissipate or spread the heat generated in electronic components to heat sinks in vehicle infotainment system, charging system, cameras, radar, lighting and power control units

- High thermal conductivity to effectively conduct heat from one surface to another

- Stable and do not degrade over time, even at high temperatures

- Electrically insulating or conductive as required with silicone free thermal interface materials options

Solutions

- Process: Die cut; Materials: Thermal interface gap pads, phase change materials, graphite sheets, thermal adhesives

Battery Pack

Battery pack heat shield / thermal insulation

Requirements

- Shield battery pack from excessive heat generated by the engine and exhaust system

Solutions

- Process: Die cut; Materials: Nonwoven, PE foam

- Process: Heat Press Forming; Materials: Non-woven + PU foam sandwich material

EV Battery Module

Thermal isolators for battery cell packs

Requirements

- Thermal insulation to separate battery cell packs and other components to reduce heat transfer between them so as to maintain the temperature of the battery cells within a desired range.

- Include fire-blocking characteristics to minimize fire propagation in the event of a thermal runaway

Solutions

- Process: Die cut; Materials: PP film, PET film, ceramic papers, aerogel sheets, silicone rubber foam sheets

- Process: Elastomer Moulding; Materials: Silicone

- Process: Particle Foam Moulding; Materials: Expanded Polypropylene (EPP)

Battery cells thermal gap interface

Requirements

- High thermal conductivity with minimal thermal impedance to dissipate or spread heat generated in battery cells to cooling systems.

- Chemically stable and not react with the battery cell materials or other materials in the system.

- Durable and able to withstand the harsh operating conditions of an EV battery system, such as high temperatures, vibration, and thermal cycling.

- Non-flammable, non-toxic, and should not release any harmful gases or particles during operation

Solutions

- Process: Die cut; Materials: Thermal interface gap pads, phase change materials, graphite sheets, thermal adhesives