Particle Foam Moulding

Lightweight, Strong, and Versatile

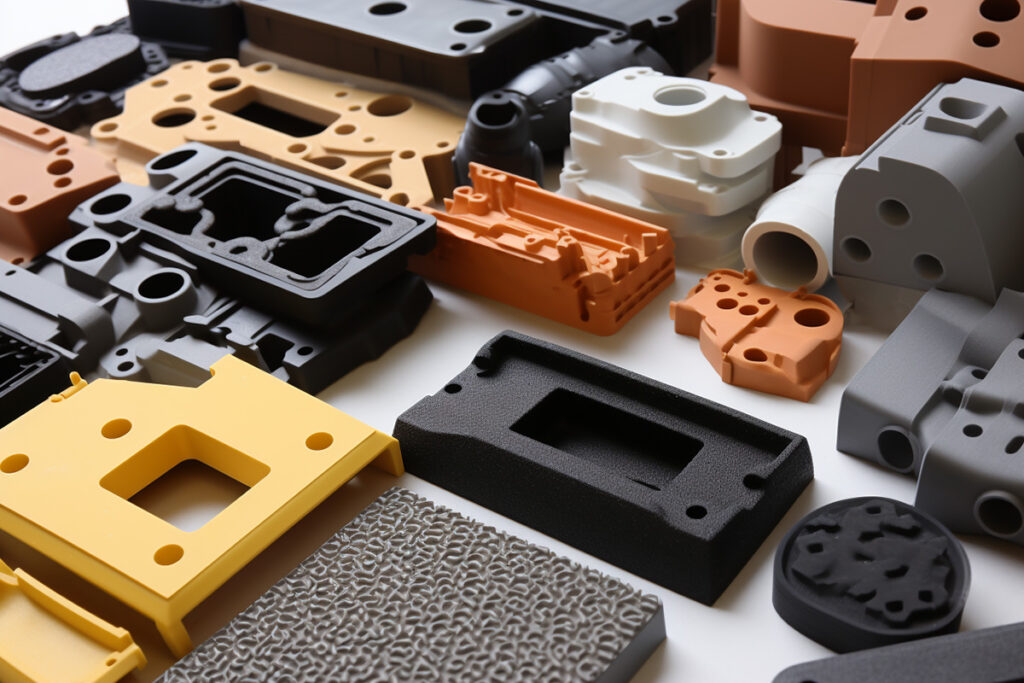

In the particle foaming process, products are created using thermoplastic foam beads that are expanded and fused together in a heated mould. Products created using particle foams are distinguished by their extremely lightweight, high dimensional accuracy and strong 3D–shaped construction that can take nearly any form. In addition to that, particle foam products have high energy adsorption at impact, low thermal conductivity and acoustical insulation. Particle foam products are also very cost-effective due to their efficient use of materials during manufacturing. In Armstrong, we provide customers with complete turnkey solutions for particle foam manufacturing from the initial design phase to production. With our extensive experience and know-how, we assure customers of the best possible results.

Our Capabilities

- Manufacturing

• Production of moulded parts up to a size of 1,200 mm x 1,800 mm and density from 20 – 200 kg/m3

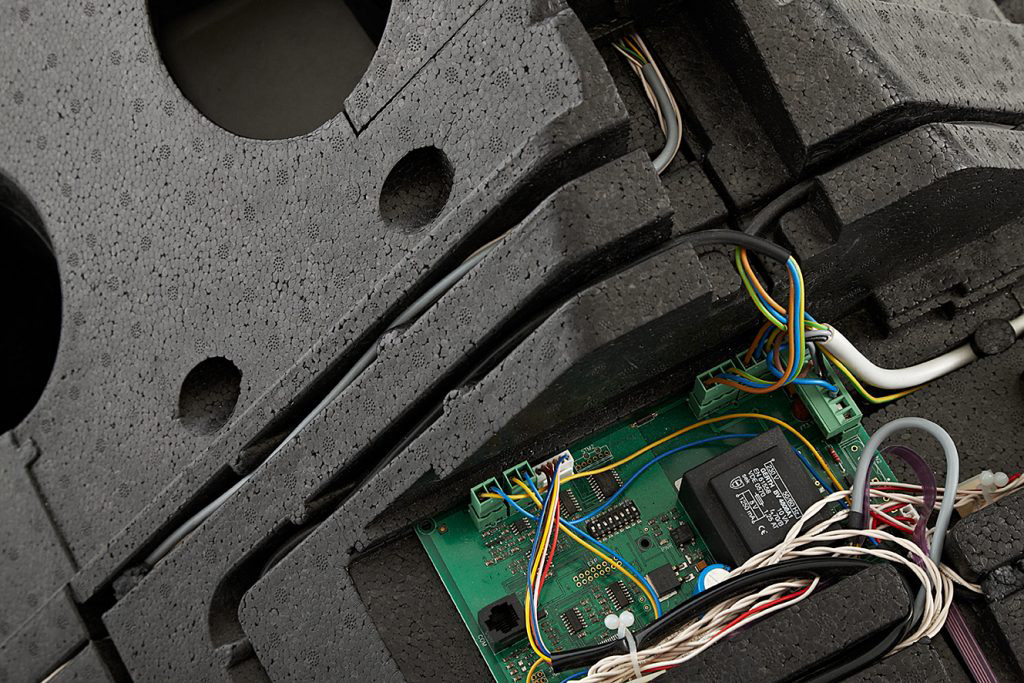

• Moulding of dual-density sections within a single part for different functions - Insert Moulding: Production of particle foam parts with plastic inserts, metal brackets and wires moulded directly into the parts for sub-assemblies

- Lamination & Coating: Coating and lamination of a variety of materials onto particle foam parts for functional and aesthetic purposes

Applications

Shock Absorption / Protection

Appliances

Products

- Internal & External Housing for Appliances

Industries

- Retail, Industrial

Applications

- Structural Parts, Shock Absorption

Materials

- EPP, EPS

Packaging

Products

- Case, Packaging, Pallet

Industries

- Retail, Industrial

Applications

- Shock Absorption

Materials

- EPP, EPS

Sports Equipment

Products

- Shoes, Helmet, Body Padding, Mat, Bicycle Seat

Industries

- Retail

Applications

- Design & Shape, Shock Absorption

Materials

- EPP, ETPU

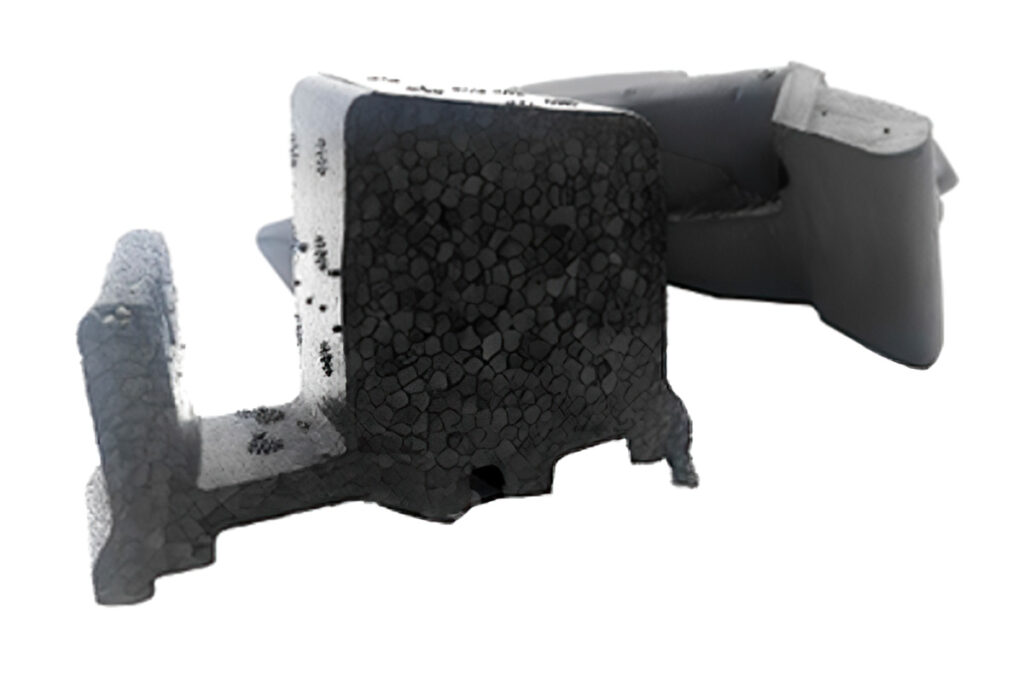

Automotive Parts

Products

- Bumper, Side & Head Impact Components, Seat Components, Knee Bolster, Battery Pack

Industries

- Automotive

Applications

- Structural Parts , Shock Absorption, Weight Reduction

Materials

- EPP

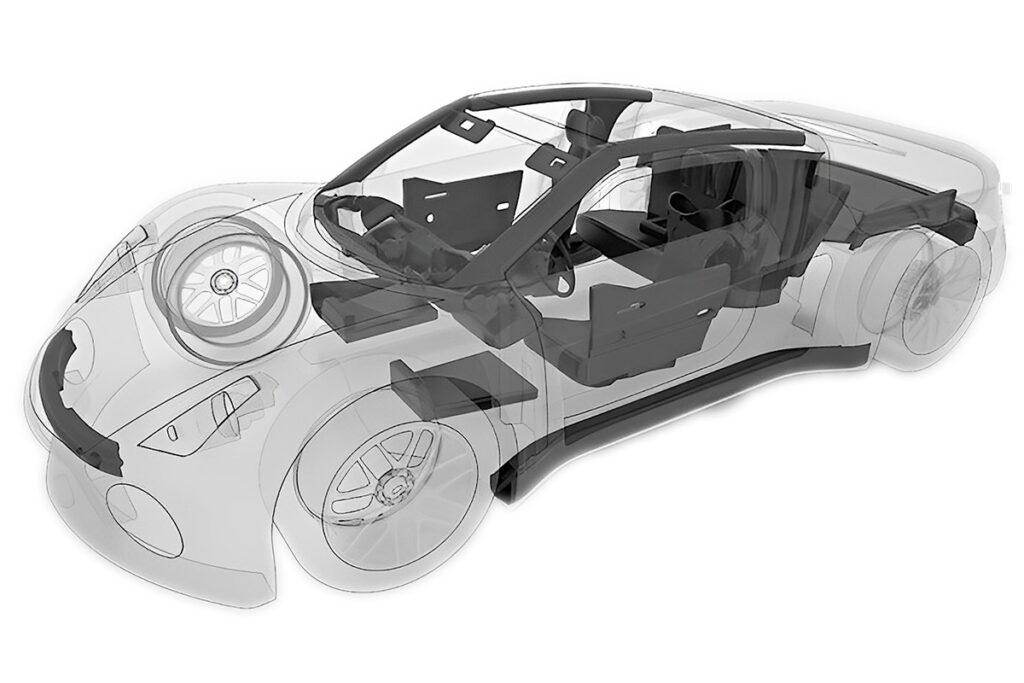

Weight Reduction

Vehicle Components

Products

- Seating components, Trunk systems, Storage System, Instrument Panel Fillers, Steering Column Fillers, Pillar Area Fillers, Floor Space Fillers, Seats, Trim Panel, Arm rest, HVAC

Industries

- Automotive, Aerospace

Applications

- Structural Parts, Weight Reduction

Materials

- EPP, EPS

Insulation

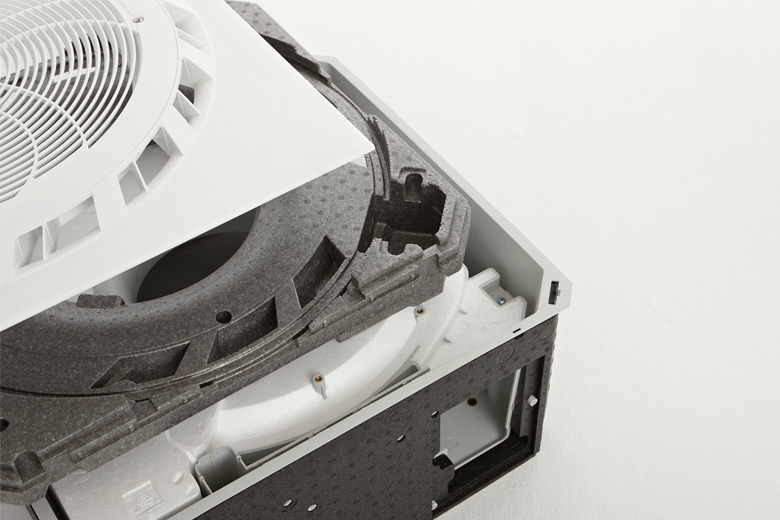

HVAC

Products

- Internal & External Housing for Pumps, Boilers, Heat Exchangers and Control Mechanisms

Industries

- Retail, Industrial, Automotive, Aerospace

Applications

- Structural Parts, Insulation

Materials

- EPP, EPS

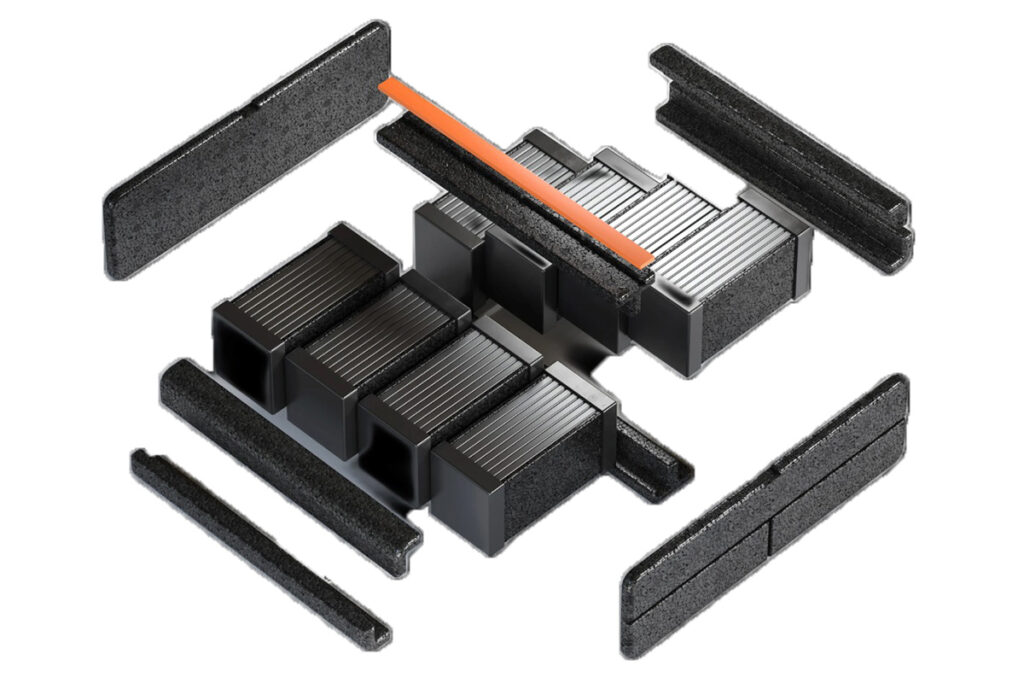

Battery Packs

Products

- Battery Packs for automotive and e-mobility devices

Industries

- Retail, Industrial, Automotive, Aerospace

Applications

- Structural Parts, Insulation

Materials

- EPP, mPPE