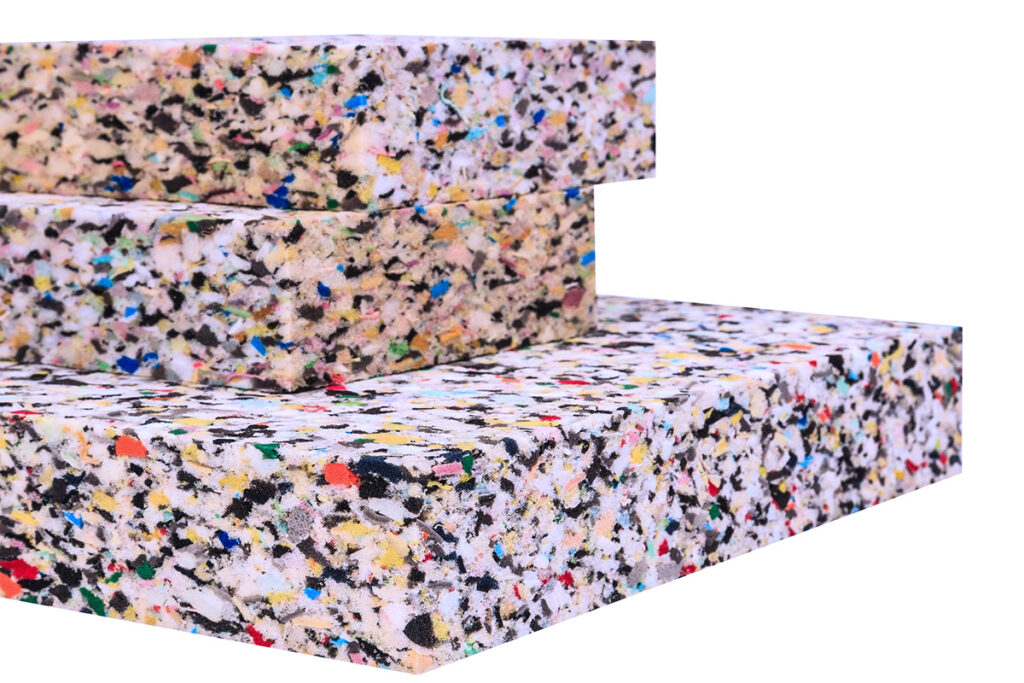

Reconstituted Foam

Utilizing Post-Industrial Waste for a Greener Future

Reconstituted foam, also known as rebonded foam, is a sustainable and environmentally friendly type of polyurethane foam made by recycling and reprocessing foam scraps and offcuts. It serves as an eco-friendly alternative to traditional foam manufacturing methods that rely on new raw materials.

To create reconstituted foam, post-industrial foam waste, like trimmings from furniture manufacturing or foam packaging scraps, is collected and shredded into small pieces. These foam particles are then mixed with a bonding agent, usually a strong adhesive, forming large blocks or sheets of foam. The adhesive helps bind the foam particles together, creating a solid and cohesive foam structure.

Reconstituted foam finds applications in various fields, such as:

- Cushioning: Used in furniture cushions, mattresses, and pillows to provide comfort and support.

- Acoustic insulation: Its porous structure makes it effective for sound absorption, suitable for soundproofing purposes.

- Packaging: Utilized as protective packaging material for delicate items during shipping.

- Sports padding: Found in gym mats, sports equipment padding, and protective gear to reduce impact and prevent injuries.

- Automotive industry: Used in car seats and interior padding.

One of the key advantages of reconstituted foam is its cost-effectiveness compared to new foam materials. Additionally, it contributes to waste reduction and sustainability by recycling foam scraps that might otherwise end up in landfills. However, the quality of reconstituted foam can vary based on the recycling and manufacturing processes employed, necessitating adherence to the required standards for its intended application.

- CH-402

- CH-403

- CH-404

- CH-406

- CH-408

- CH-411

- CH-416

- 60

- 70

- 80

- 100

- 120

- 150

- 200