Robotics

Noise, Vibration & Harshness Solutions

Addressing noise, vibration, and harshness (NVH) challenges in robotics requires a combination of engineering techniques and materials science to ensure performance, safety, and user comfort. As robotics applications expand into more sensitive environments, such as healthcare, homes, and public spaces, NVH control will play an increasingly critical role in design and implementation.

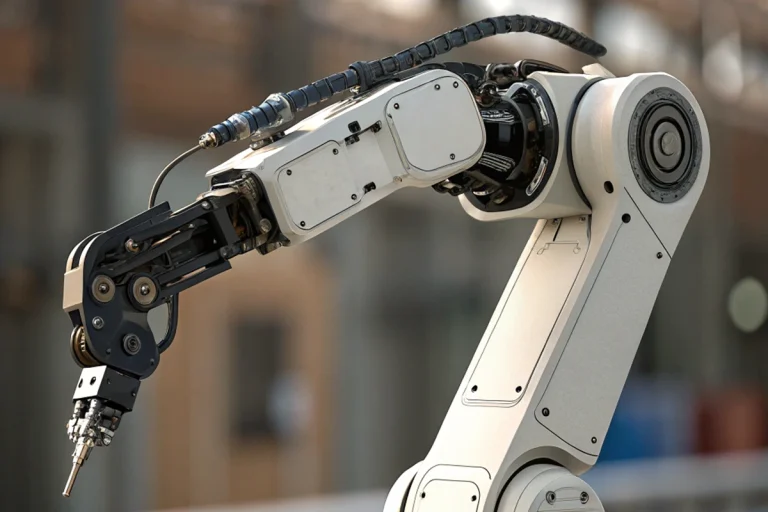

Manipulator Arm

Articulated Arms & Joints Rubber Bushings

Requirements

- Provide cushion between the moving parts to dampen vibrations, reducing wear and tear, and ensuring smooth and precise movements

- Flexible yet sturdy, with low compression set, excellent wear and fatigue resistance, and adaptable temperature and chemical resistance for diverse applications

Solutions

- Process: Elastomer Moulding; Materials: Natural Rubber, EPDM, CR, Urethane

Locomotion Parts

Shock-absorbing & Vibration Dampening Components

Requirements

- Absorb shocks and vibration from uneven terrain or when robotic legs or wheels contact the ground

- Durable and resilient with excellent energy and vibration absorption capacity

Solutions

- Process: Elastomer Moulding; Materials: Urethane, NBR, CR

- Process: Die-cut; Materials: Urethane, NBR, CR

Frames & Structural Components

Vibration-absorbing Pad & Inserts

Requirements

- Dampen vibration to reduce strain on the frame and critical components during operation in dynamic environments

Solutions

- Process: Elastomer Moulding; Materials: Urethane, CR, NBR

- Process: Die-cut; Materials: Urethane, CR, NBR, Microcellular PU

- Process: Reaction Injection Moulding; Materials: PU