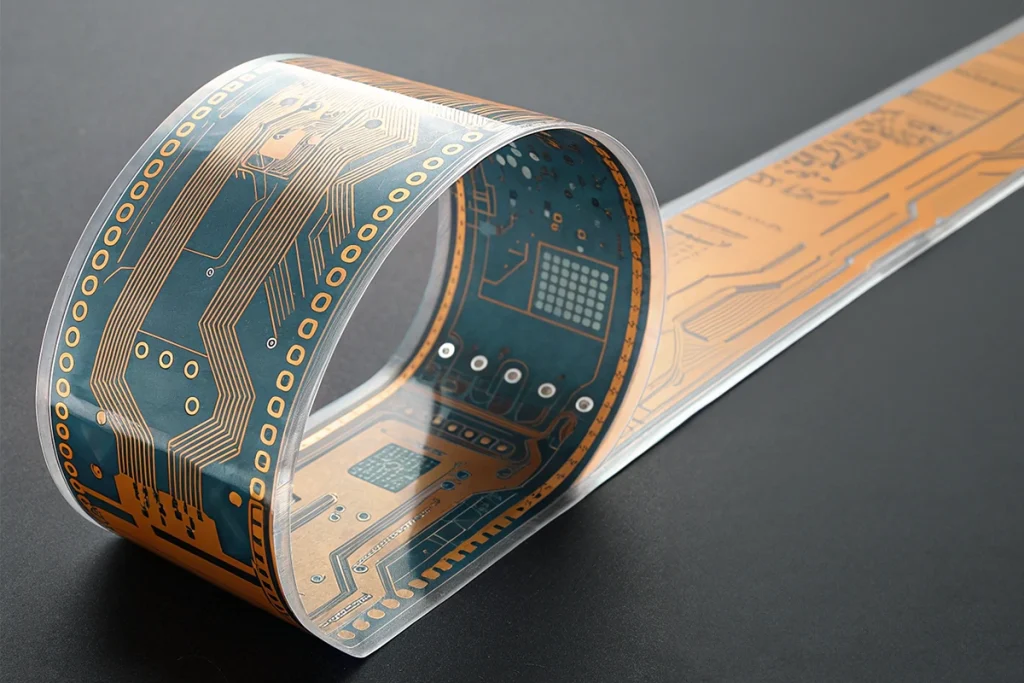

Flexible Printed Circuits

At Armstrong, we provide flexible printed circuits (FPCs) that are meticulously engineered to meet the unique demands of advanced robotic systems. We offer a wide range of customization options, enabling manufacturers to select the ideal materials and designs to optimize each robot’s performance, durability, and reliability.

Customization options available:

Substrate Materials

Polyimide: High-temperature resistance, excellent flexibility, suitable for most robotic applications.

Polyester (PET): Cost-effective, ideal for low-stress applications or where minimal bending is required.

Thermoplastic Polyurethane (TPU): Provides stretchability for soft robotics and wearable applications.

Polyethylene Naphthalate (PEN): Offers moderate heat resistance and lower moisture absorption than PET, suitable for more demanding environments.

Layer Configuration

Single-Layer FPC: Simple, cost-effective design for low-complexity circuits with minimal bending.

Double-Layer FPC: Adds a second layer for more complex routing and increased circuit density, while maintaining flexibility.

Multi-Layer FPC (up to 4 layers): Allows high-density interconnects for complex circuits, such as those required in humanoid robots or medical devices.

Rigid-Flex: Combines rigid and flexible sections, providing stability in critical areas and flexibility elsewhere. Useful for robotic systems with both stationary and moving parts.

Inks

Silver Conductive Inks: Known for high conductivity and flexibility, silver inks are widely used for reliable signal transmission.

Carbon Conductive Inks: Durable and cost-effective, carbon inks offer stable conductivity under repeated stress.

Flexible Dielectric Inks: Essential for insulating multiple conductive layers while maintaining circuit flexibility.

High-Temperature Dielectric Inks: Used in environments with elevated temperatures, maintaining insulation without degrading.

UV-Curable Protective Inks: Forms a durable, scratch-resistant layer to shield circuits from environmental exposure.

Component Integration

Embedded Components: Passive components like resistors or capacitors can be embedded directly onto the FPC, reducing bulk.

LED Integration: Often used for status indicators or visual feedback in robotic systems.

Sensor Embedding: Integrating sensors (e.g., temperature, pressure) into the FPC can provide additional functionality, particularly in end-effectors or wearable robots.

Connector Options

ZIF (Zero Insertion Force) Connectors: Reliable and easy-to-use connectors for applications where the circuit might need frequent disconnection.

Custom Pin Configurations: Tailored pin layouts to match specific robotic system needs, reducing wiring complexity.

Heat-Sealed Terminations: Improves durability in applications that may experience vibration or shock, like drones or industrial robots.

Special Coatings And Treatments

Waterproof Coatings: For use in drones, underwater robots, and robots exposed to moisture or liquids.

UV-Resistant Coatings: Prevents degradation in outdoor robotic applications.

Anti-Corrosion Coatings: Essential for environments exposed to chemicals or other corrosive substances, such as industrial robots.