Electric Vehicle

Noise, Vibrations & Harshness Solutions

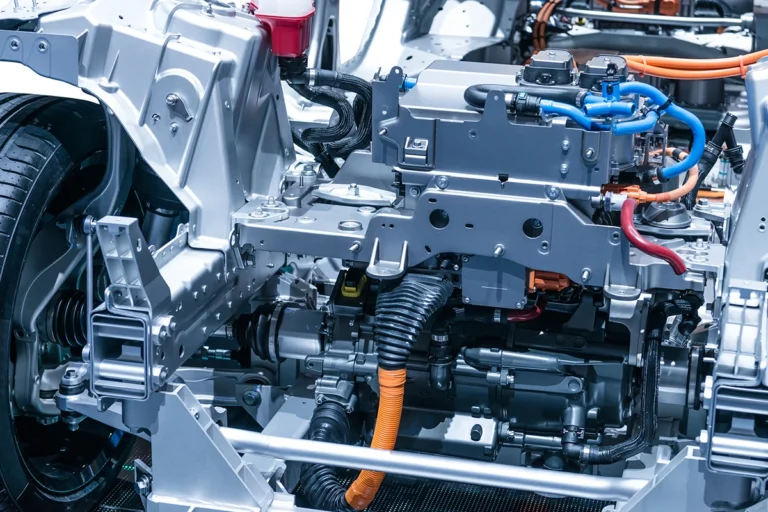

Although EVs are quieter than internal combustion engine (ICE) cars, they face unique noise challenges. At higher speeds, road and wind noise become more noticeable without engine sounds to mask them. Additionally, noise from motors, cooling systems, and regenerative braking stands out. Tackling these issues is essential for improving the acoustic comfort and driving experience of EVs.

Interior / Cabin

Inserts or paddings for headliners, rear shelf, pillar, floor panel, dashboard, AC air outlet, AC vent pipe, sunroof cover, wire harness, centre console, storage box, etc.

Requirements

- To prevent unwanted outside noise from entering the passenger compartment

- To cushion shock impact and dampen vibration from any moving parts or components

Solutions

- Process: Die cut; Materials: PU foam, PE foam, Nonwoven, Rubber Sponge

- Process: Heat Press Forming; Materials: PE foam

- Process: Reaction Injection Moulding; Materials: PU

Door Module

Soundproofing Shield / Mat

Requirements

- To prevent unwanted outside noise from entering the passenger compartment

- To cushion shock impact and dampen vibration from any moving parts or components

Solutions

- Process: Die cut; Materials: PU foam, PE foam, Nonwoven

- Process: Heat Press Forming; Materials: PE foam

- Process: Vacuum Forming; Materials: PE foam

- Process: Reaction Injection Moulding; Materials: PU

Wire Harness Grommets

Requirements

- To protect electrical wiring from damage through door holes and openings

- Able to suppress rattling, and have good resistance to cold and heat

Solutions

- Process: Elastomer Moulding; Materials: EPDM

Paddings

Requirements

- To cushion shock impact and dampen vibration from any moving parts or components

- Low odour or odourless materials

Solutions

- Process: Die cut; Materials: PU foam, PE foam, Nonwoven

- Process: Heat Press Forming; Materials: PE foam

Trunk

Inserts or paddings for trunk shelf, trunk cover, floor panel, wire harness, tool kit storage compartment, etc.

Requirements

- To prevent unwanted outside noise from entering the passenger compartment

- To cushion shock impact and dampen vibration from any moving parts or components

Solutions

- Process: Die cut; Materials: PU foam, PE foam, EPDM foam

- Process: Heat Press Forming; Materials: PE foam, Sandwich Materials

- Process: Reaction Injection Moulding; Materials: PU

Audio System

Speaker Mounting

Requirements

- Air-tight speaker gasket to seal the speaker to the speaker enclosure at the door and dashboard

- Able to dampen vibration and insulate sound at the interface area

Solutions

- Process: Die-cut; Materials: PU foam, PE foam, EVA foam, EPDM foam

HVAC System

Air Duct System

Requirements

- To dampen noise and vibrations from airflow and HVAC components

- Able to prevent condensation in air ducts to avoid moisture buildup

- Lightweight, flexible and easy to install

Solutions

- Process: Twin-sheet Thermoforming; Materials: PE foam, Nonwoven PET

- Process: Die-cut; Materials: PE foam, PU foam, rubber sponge

Wheel Arch

Wheel Housing Padding

Requirements

- To dampen vibrations from the tires and suspension, and reduce noise from tire-road contact, debris, and water impacts.

- Lightweight, easy to install, and durable enough to handle vibrations, temperature changes, and moisture.

- Moisture-resistant to prevent water buildup and protect nearby components from corrosion.

Solutions

- Process: Heat Press; Materials: Nonwoven PP/PET

Steering System

Steering Joint Bushings

Requirements

- To prevent metal-to-metal contact to ensure longevity of the vehicle’s steering system

- To act as a cushion to absorb vibration between the wheels and steering joints for the driver’s comfort

Solutions

- Process: Elastomer Moulding; Materials: PU, NR, EPDM, NBR

Suspension System

Suspension / Shock Absorber Bushings

Requirements

- To prevent metal-to-metal contact to ensure longevity of the suspension arms

- To act as a cushion to stop the transmission of vibration from the wheels to the vehicle chassis

Solutions

- Process: Elastomer Moulding; Materials: PU, NR, EPDM, NBR