Electric Vehicle

Electrical Insulation Solutions

Dielectric barrier and insulation solutions are essential for the safe and reliable operation of electric vehicles, preventing shocks, electrical leakage, and high-voltage issues like arcing and short circuits. They enhance efficiency and performance while ensuring environmental safety. Additionally, these solutions act as thermal barriers between battery components, reducing the risk of thermal events and thermal runaway.

Vehicle Electronics / Equipment

Electrical barrier and insulation between different parts or components in a circuit

Requirements

- High dielectric strength to withstand high voltages without breakdown or leakage, while maintaining a low dielectric constant to reduce signal distortion

- Good thermal stability, resistant to degradation or melting at operational temperatures

- Resistant to chemicals and solvents commonly present in the environment.

Solutions

- Process: Die-cut; Materials: Polyimide film, PET film, Vulcanized fiber

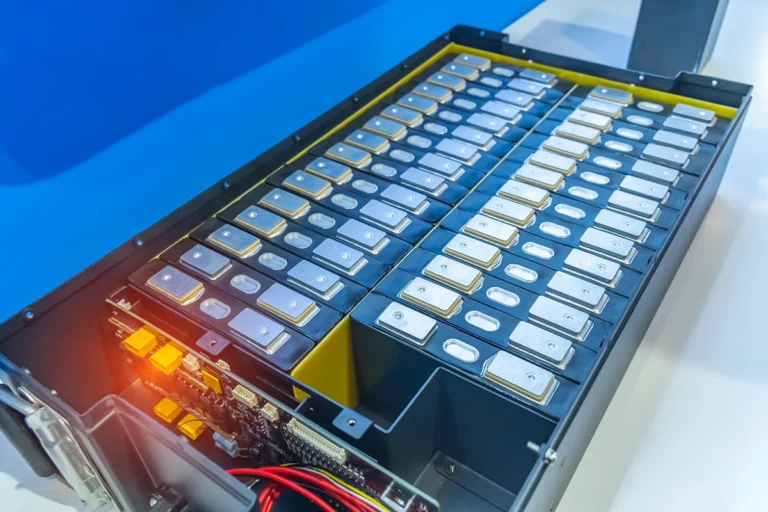

Battery Module / Pack

Insulating sheets, pads, and separator films

Requirements

- High dielectric strength to handle high voltages without breakdown or leakage, and strong mechanical strength to resist vibrations, impacts, and compression without cracking or deforming

- Excellent thermal stability to endure high operational temperatures without degrading, and meet flame retardance standards like UL94 5VA to prevent ignition or fire spread

- Resistant to chemicals and solvents commonly present in the environment.

Solutions

- Process: Die-cut; Materials: Polyimide film, PET film, Vulcanized fiber, Silicone sheet / foam, PTFE sheet