Noise, Vibrations & Harshness Solutions

Safety and reliability are of paramount importance in EV battery design. They ensure the well-being of occupants, protect the environment, and maintain the vehicle’s performance over its lifespan. At Armstrong we combine our innovative manufacturing processes, materials, and technologies from our experience in advanced industries to provide the following solutions that enhance EV battery safety and reliability.

Seals & Gaskets

Seals and gaskets create a barrier against environmental factors such as moisture, dust, dirt, and contaminants. They play a crucial role in safeguarding the sensitive battery components from external elements that could potentially impact the battery’s performance or lifespan. Moreover, seals and gaskets effectively absorb and dampen vibrations and shocks resulting from road conditions and vehicle movement. This protection shields the battery cells and connections from mechanical stress and potential damage.

Our Custom Solutions:

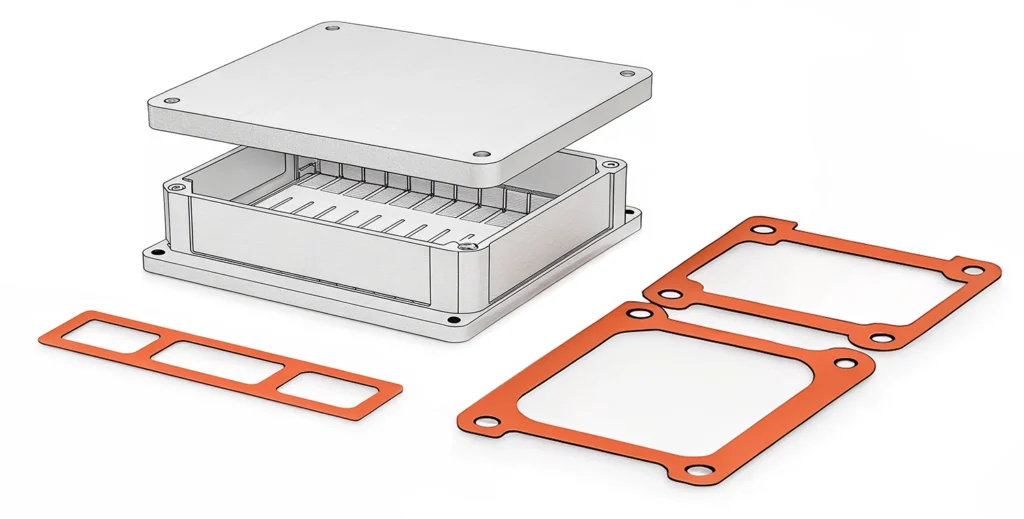

Battery Enclosure Gaskets

Depending on the specific needs of the customer, we utilize a variety of die-cutting methods to fulfill their requirements. Our range of performance materials, sourced from leading raw material manufacturers, encompasses a diverse array of options, spanning from silicone foam rubbers to butyl-coated PVC and micro-cellular PUR foams. These materials offer a range of advantageous properties, including low compression set characteristics and fire-resistance capabilities.

Depending on the specific needs of the customer, we utilize a variety of die-cutting methods to fulfill their requirements. Our range of performance materials, sourced from leading raw material manufacturers, encompasses a diverse array of options, spanning from silicone foam rubbers to butyl-coated PVC and micro-cellular PUR foams. These materials offer a range of advantageous properties, including low compression set characteristics and fire-resistance capabilities.

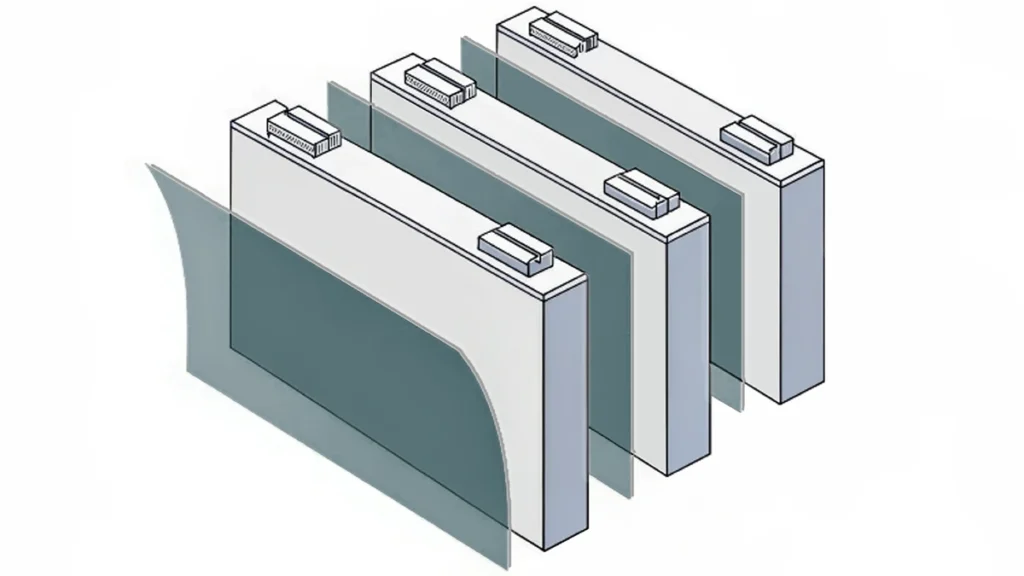

Compression Pads

Compression pads are vital for EV battery pack design, ensuring performance, safety, and longevity. They distribute loads, absorb vibrations, and maintain even pressure to protect sensitive components from impacts. Moreover, they optimize thermal management, enabling consistent battery performance. These pads also offer electrical isolation, assist in precise component alignment during assembly, reduce resonances, and improve serviceability for easier maintenance.

Our Custom Solutions:

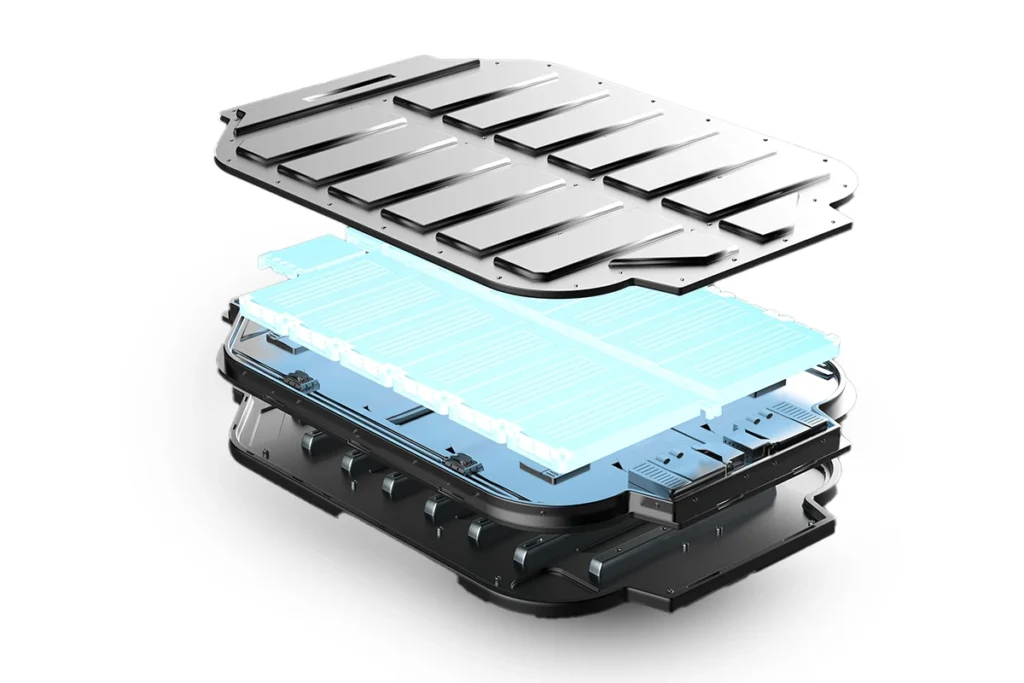

Battery Cell Compression Pads

Compression pads used within the battery module must strike a balance between being firm enough to hold the battery cells in place and compressible enough to withstand dimensional changes in the pouch cells over the battery's lifespan. To address this challenge, we offer solutions featuring micro-cellular PUR foams and silicone foams that are specifically suited for these requirements. These materials possess an exceptional ability to consistently apply force across various compression levels, ensuring optimal performance and longevity.

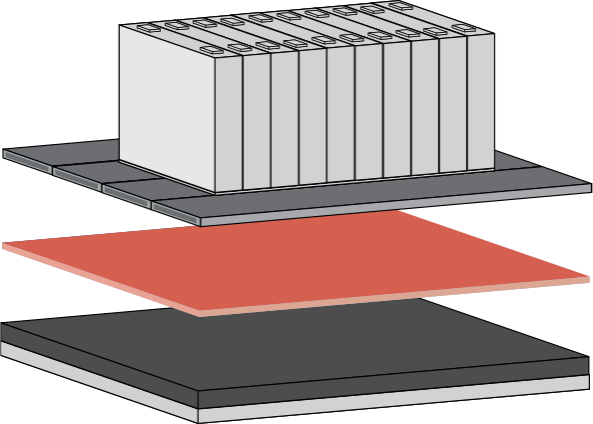

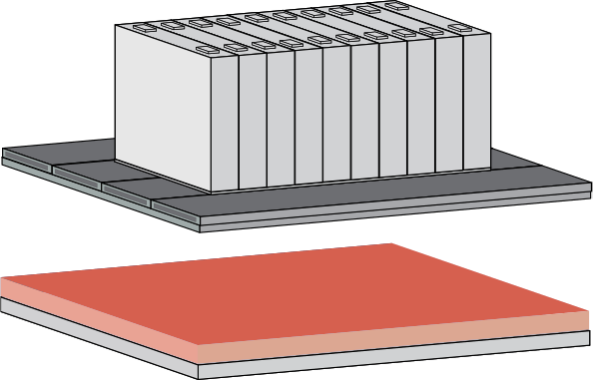

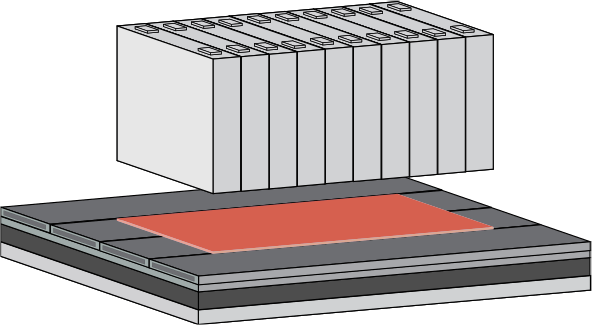

Cooling Plate Cushioning Pad

Safeguarding the battery pack from shocks and vibrations caused by the unpredictable nature of road surfaces is crucial for ensuring its performance. To achieve this, a micro-cellular PUR foam cushioning pad can be placed between the battery case and cooling plate. These foams offer exceptional resilience, rebound properties, and low compression set, effectively dampening vibrations and providing noise, vibration, and harshness (NVH) protection. They also enhance safety with superior flame resistance, extending the battery's lifespan.

Impact Protection Components

In the event of an impact or collision, there is a risk of cell damage from punctures or deformations, which can lead to the release of harmful chemicals or thermal runaway events. Therefore, impact protection components play a crucial role in battery module design, ensuring the safety of the battery cells, maintaining structural integrity, and safeguarding both the environment and the vehicle’s occupants.

Our Custom Solutions:

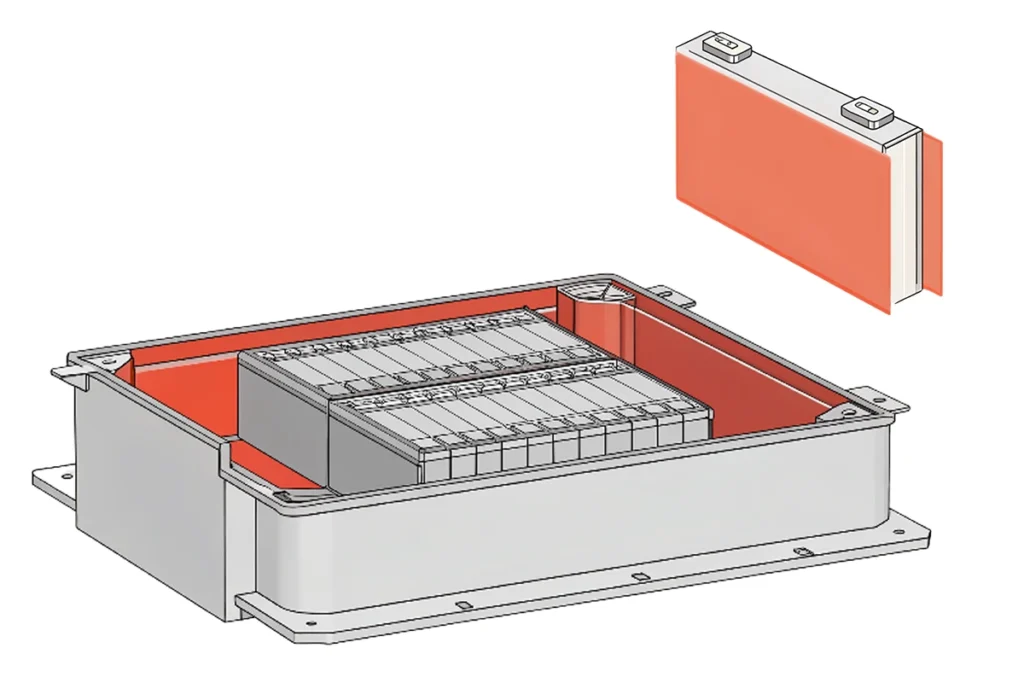

Structural Support & Crash Absorber Pad

In the EV battery module design, structural support and crash absorber pads must be strong, lightweight, and crash-resistant to protect the battery during collisions while meeting regulatory standards and cost-effectiveness. In this context, Expanded Polypropylene (EPP) serves as an ideal material choice thanks to its lightweight composition, exceptional energy absorption capacity, impact resilience, durability, insulating qualities, superior flame resistance, design flexibility, and environmental resistance. At Armstrong, we specialize in providing custom-molded EPP structural support and crash absorber pads tailored to meet precise requirements for EV battery protection.

Thermal Interface Components

Thermal interface components are vital for enhancing the performance, safety and reliability of EV battery packs. By efficiently transferring and managing heat between battery elements like cells and cooling systems, these components help maintain optimal operating temperatures, preventing overheating and thermal runaway risks. High-quality thermal interface materials minimize potential short circuits and hotspots, reducing safety hazards. Additionally, proper thermal management prolongs battery cell lifespan, decreasing degradation and enhancing long-term reliability.

Our Custom Solutions:

Thermal Adhesive Tapes

Thermal adhesive tapes are vital components in EV battery design, serving to enhance heat transfer and ensure secure bonding between battery cells, cooling components, and structural elements. These tapes facilitate efficient heat dissipation, maintain even temperature distribution, and offer vibration damping properties. Thermal adhesive tapes are applied between battery cells, to cooling structures, and within battery modules, promoting optimal thermal management and structural integrity. At Armstrong, we offer a diverse range of die-cut thermal adhesive tapes, including both silicone and silicone-free options, to effectively address these requirements.

Flame Barrier Components

Flame barrier components serve as a protective shield against fires and thermal events, these components curtail flame spread, mitigating risks. By containing potential fire incidents, they minimize damage to battery elements and surroundings, ensuring occupant and environmental safety. The application of robust flame barrier materials promptly confines thermal runaway, enhancing overall battery pack safety and bolstering electric vehicle reliability.

Our Custom Solutions:

Thermal Barrier Films

Thermal barrier films are thin layers or sheets of material designed to provide insulation and mitigate the transfer of heat between components or surfaces. These films are used to create barriers that help contain and dissipate heat, prevent the spread of flames, and enhance overall safety in situations where elevated temperatures can pose a risk. They are made from a variety of materials, including polymers, ceramics, and composites, to offer specific thermal and mechanical properties. At Armstrong, we offer a comprehensive assortment of thermal barrier films to cater to diverse needs.

Flame-Retardant Adhesive Tapes

Flame-retardant adhesive tapes are specialized tapes designed with both adhesive properties and flame resistance. These tapes are employed to securely fasten and insulate components within the battery pack while also mitigating the risk of flame propagation and fire hazards. Armstrong provides a diverse range of solutions designed to bond these materials to battery cells, modules, and pack structures, ensuring both reliable performance and heightened safety measures.

Dielectric barriers & insulators

Dielectric barriers & insulators act as a protective barrier, isolating electrical components and preventing short circuits, reducing safety hazards. By effectively containing electrical currents, insulations minimize the risk of fire and potential damage to the battery pack. Moreover, they contribute to the pack’s reliability by maintaining consistent electrical performance, preventing leakage currents, and minimizing interference.

Our Custom Solutions:

Electrical Tapes & Films

Electrical tapes and films are essential components in EV battery design, serving multiple purposes to ensure safety and reliability. They provide insulation to prevent short circuits and maintain electrical separation between components such as battery cells, terminals, and connectors. Notably lightweight, cost-effective, and flame retardant, these materials fulfill stringent electrical barrier and insulation criteria, thereby contributing to the overall security and dependability of the EV battery system.