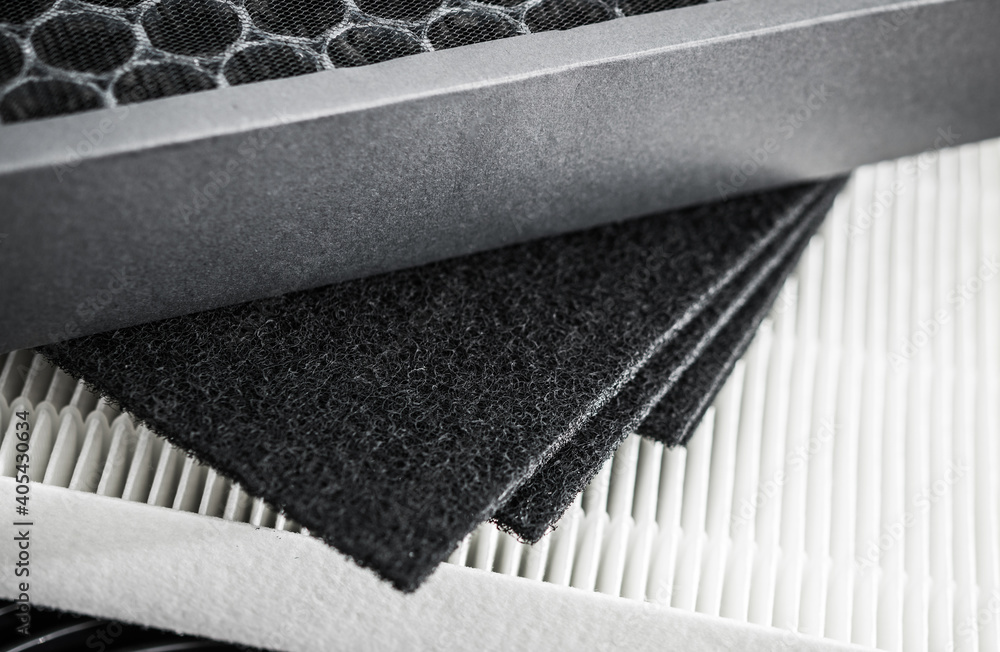

With years of experience in the industry, Armstrong has gained a reputation for delivering high-quality and reliable air filter components made of foam and non-woven materials that meet the strictest industry standards and regulations of the automotive industry.

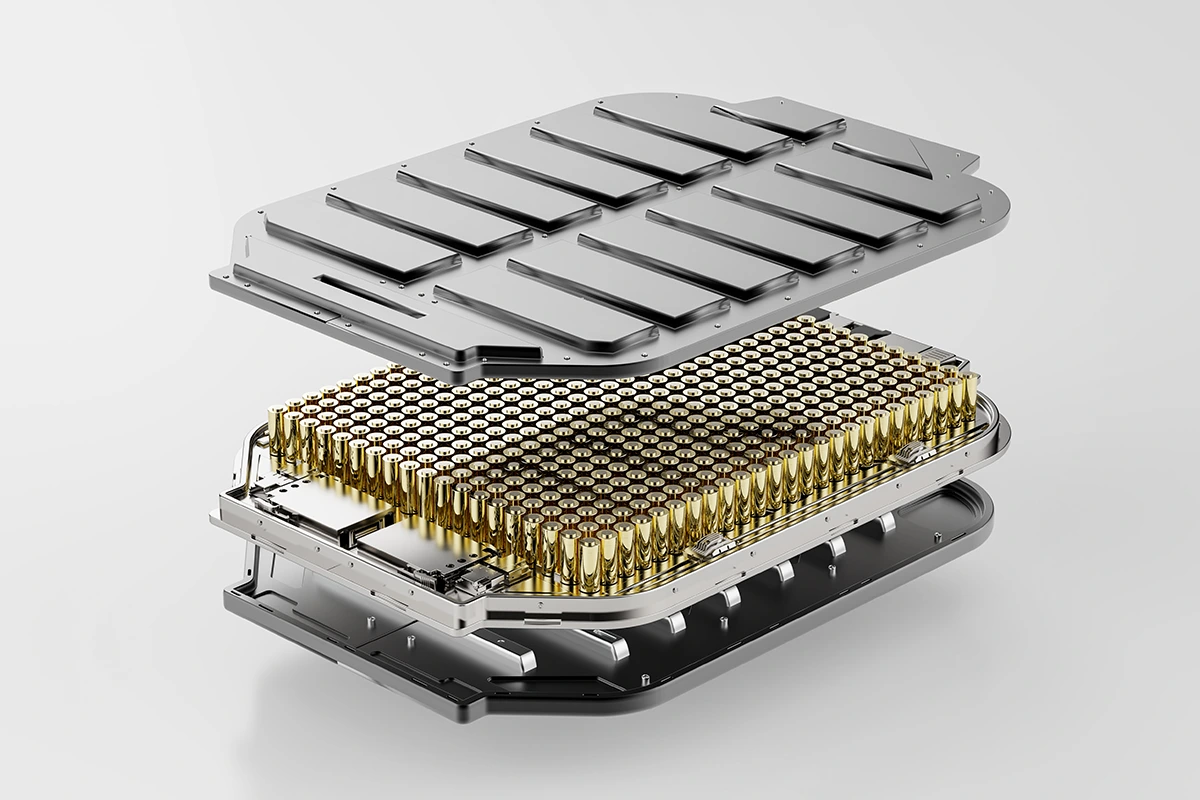

Electric Vehicle Noise, Vibrations & Harshness Solutions Electric Vehicle Solutions Noise, Vibrations & Harshness Shock & Impact Protection Thermal Management Dielectric Barrier & Insulation Sealing & Gasketing EV Battery Industry Solutions > Transportation & Mobility Automotive Rail & Mass Transit Personal Mobility Safety and reliability are of paramount importance in EV battery design. They ensure […]

In electric vehicles (EVs), seals and gaskets ensure proper function and safety by blocking contaminants from sensitive components like batteries, motors, electronics, and HVAC systems. They protect enclosures and ports, reduce energy loss, support air suspension, and maintain weather-tight cabins. These elements enhance EV reliability, performance, and sustainability, contributing to long-term efficiency.

Dielectric barrier and insulation solutions are essential for the safe and reliable operation of electric vehicles, preventing shocks, electrical leakage, and high-voltage issues like arcing and short circuits. They enhance efficiency and performance while ensuring environmental safety. Additionally, these solutions act as thermal barriers between battery components, reducing the risk of thermal events and thermal runaway.

Effective thermal management is crucial for electric vehicles (EVs) to maintain optimal temperatures for key components like the motor, power electronics, and battery. Proper heat regulation during operation maximizes energy efficiency, extends driving range, and ensures component reliability and longevity, enabling EVs to achieve peak performance and efficiency.

Impact protection solutions are vital for EVs, ensuring occupant safety and vehicle integrity. They absorb and distribute collision forces, minimizing passenger injury and protecting the costly battery pack. These solutions also maintain structural integrity, meet safety standards, and build consumer confidence, promoting wider adoption of EVs.

Although EVs are quieter than internal combustion engine (ICE) cars, they face unique noise challenges. At higher speeds, road and wind noise become more noticeable without engine sounds to mask them. Additionally, noise from motors, cooling systems, and regenerative braking stands out. Tackling these issues is essential for improving the acoustic comfort and driving experience of EVs.

With expertise in noise, vibration, heat, and safety management, Armstrong empowers electric vehicle (EV) manufacturers to overcome challenges and enhance the performance of next-generation EVs.

Robotics Flexible Printed Circuits Robotics Solutions Sealing & Gasketing Noise, Vibration & Harshness Thermal Management Shock & Impact Protection Electrical Insulation Flexible Printed Circuits At Armstrong, we provide flexible printed circuits (FPCs) that are meticulously engineered to meet the unique demands of advanced robotic systems. We offer a wide range of customization options, enabling manufacturers […]

Robotics Shock & Impact Protection Robotics Solutions Sealing & Gasketing Noise, Vibration & Harshness Thermal Management Shock & Impact Protection Electrical Insulation Flexible Printed Circuits Electrical insulation in robotics is essential for ensuring components operate safely and efficiently by preventing electrical leakage and short circuits. Proper insulation safeguards not only the internal functioning of the […]