Functional Printing

Printed Innovation at Your Fingertips

At Armstrong, we develop and manufacture printed electronics circuits and sensors. With over a decade of experience, we are proud to offer our customers superior quality products that are designed to meet the most rigorous requirements and provide superior performance in terms of longevity, durability, and reliability.

Whether you’re looking for simple or complex designs, our team can work with you to find the perfect solution for your project. With our fast fulfilment times and customisable options, Armstrong is the perfect choice for any sized business.

Our Capabilities

- Automated industrial screen printing lines

- Semi-automated SMT production line

- Precision die-cutting

- Lamination and coating

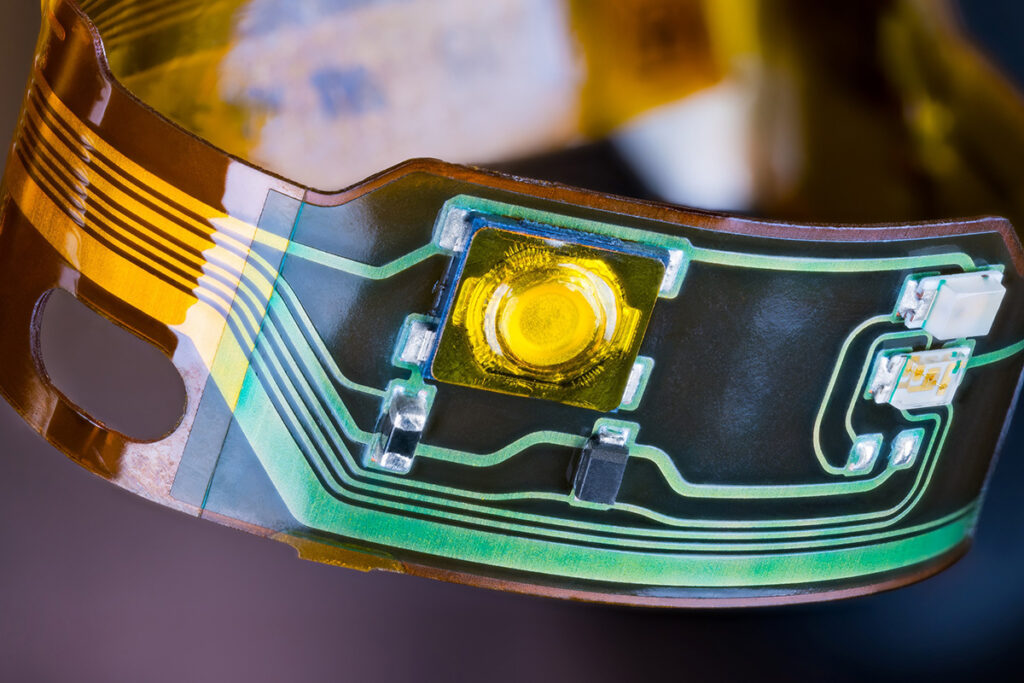

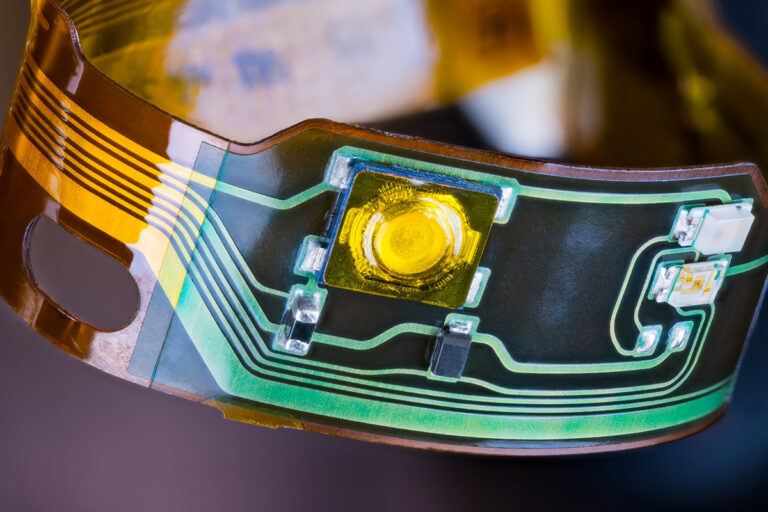

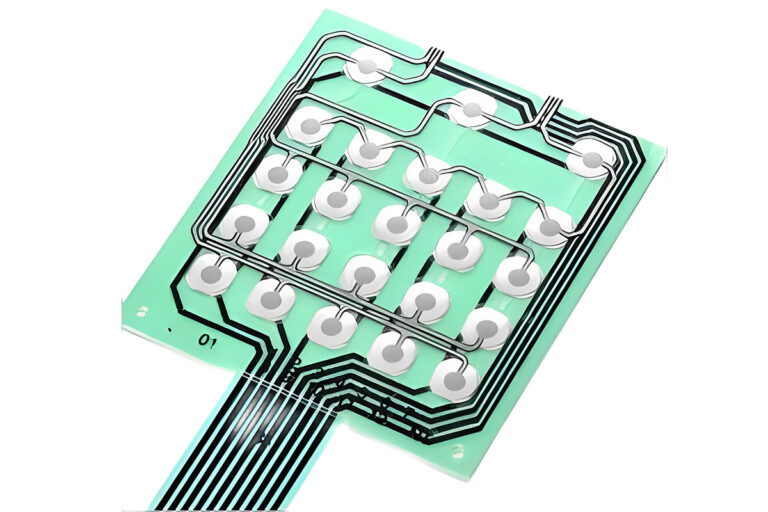

- Custom assembly, including membrane keypad and LED assembly

- Functional Testing

- Product-specific packaging

Key Features

Printing methods

- Sheet-based screen printing

- Inks - Silver-based, carbon-based, dielectric-based, and more (Thermal / UV Ink)

Substrate

- PET, PC, PEN, PI, and more

Layers

- Single- and double-sided printing, up to 4 layers

Patterning accuracy

- Printable micro conductor up to 20μm

- Spacing within conductor 30μm

- Positioning accuracy ± 10μm

Processing size

- Up to 400 x 500mm

Component attachment methods

- Surface mount

SMD components

- Surface mount

- 0402, 0606, 0805, SOP8, QFN

Value-add

- Mechanical assembly, coating, lamination, packaging

Applications

The flexible printed circuit is produced on a thin insulating polymer film with a pattern of conductive traces printed onto the substrate. The flexible structure makes it possible to mount the printed circuit on any curved organic shaped surfaces.

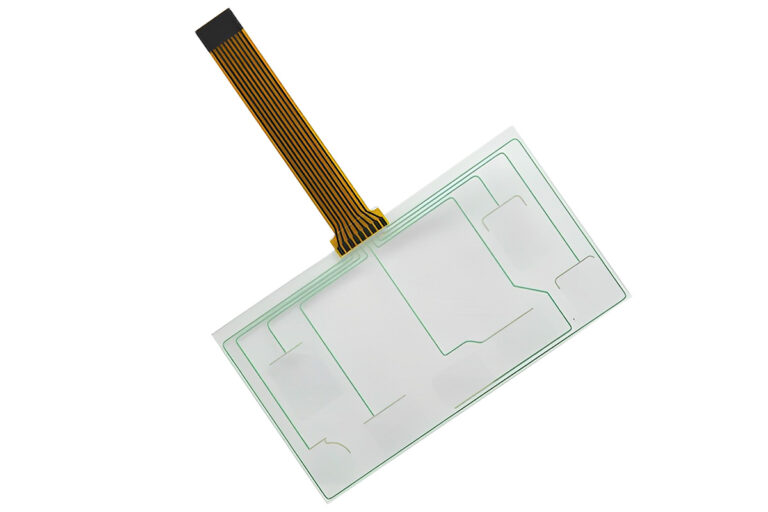

A membrane switch is a user interface device that is constructed of flexible layers over a printed circuit. It is typically used as a switch to turn a device on or off. The construction of a basic membrane switch generally include a membrane overlay, spacer, printer circuit, rear adhesive, and tail filler.

Flexible Capacitive Touch Sensor

Flexible capacitive touch sensors can be constructed using the functional printing process. In this process, the most commonly used sensor structures, interdigitated capacitors (IDCs) are printed on flexible polymers or fabrics.

Flexible Rain Sensor

In the construction of the flexible rain sensor board, narrow strips of conductors are printed on flexible polymers. The flexible sensor board acts as a variable resistor when rain droplets complete the circuits on the board’s printed conductors. The wetter the board the more current that will be conducted.

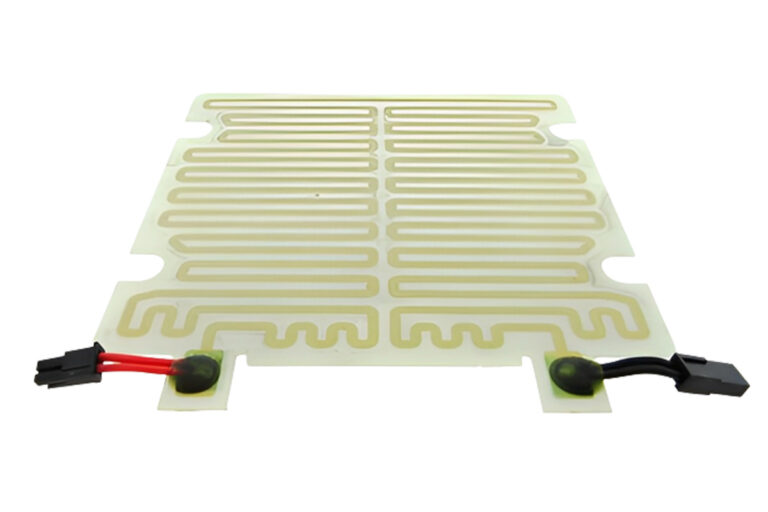

To manufacture flexible printed heating elements, conductive busbars and resistive heating elements are printed on flexible polymers. In this process, electrically resistive inks are used to turn current into heat.