Reaction Injection Moulding

Unveiling the Future of Moulding

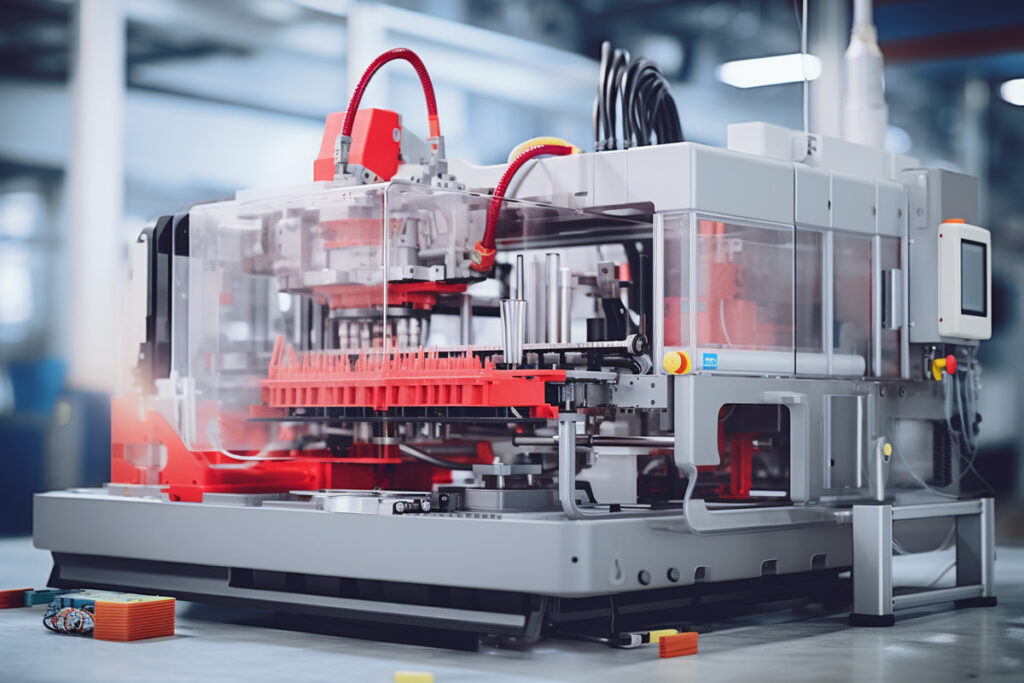

Armstrong offers a wide range of moulded foamed polyurethane rubber (PUR) solutions with Reaction Injection Moulding (RIM) process. With more than a decade of experience in RIM process, we create high-quality custom moulded foamed PUR parts that are designed to be highly functional and durable.

Our engineering team works with our customers to develop customized solutions tailored to their exact requirements. We also provide comprehensive support services throughout the production process to ensure quality standards and cost efficiencies are met. With our expertise and attention to detail, you can trust us to deliver products that meet all your expectations.

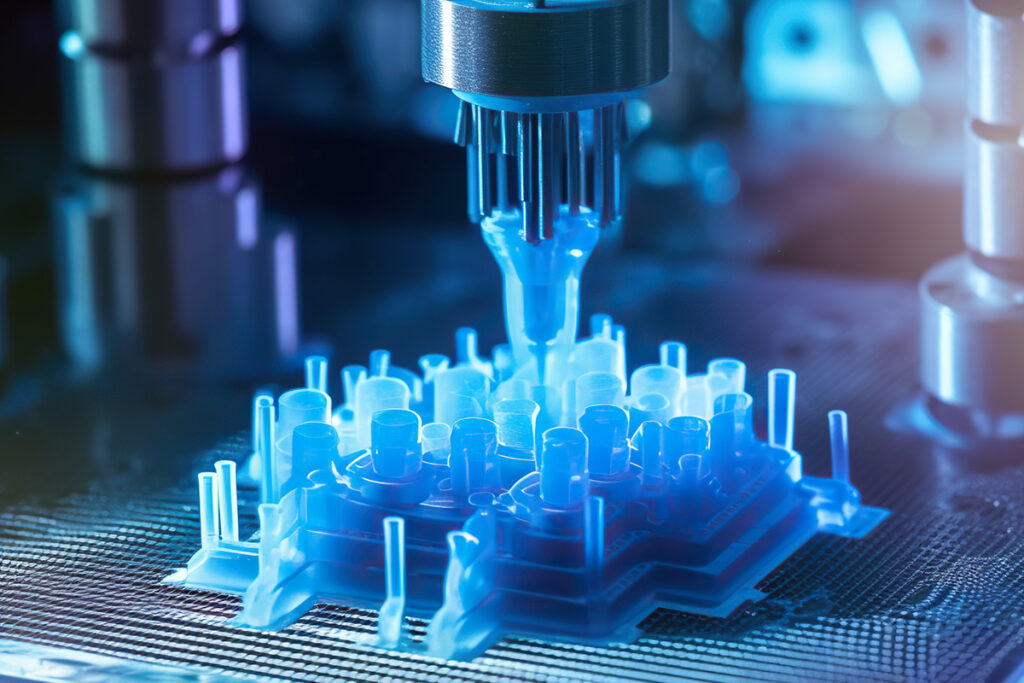

What Is Reaction Injection Moulding?

Armstrong offers a wide range of moulded foamed polyurethane rubber (PUR) solutions with Reaction Injection Moulding (RIM) process. With more than a decade of experience in RIM process, we create high-quality custom moulded foamed PUR parts that are designed to be highly functional and durable.

Our engineering team works with our customers to develop customized solutions tailored to their exact requirements. We also provide comprehensive support services throughout the production process to ensure quality standards and cost efficiencies are met. With our expertise and attention to detail, you can trust us to deliver products that meet all your expectations.

Our Capabilities

- Manufacturing

• Production of flexible and rigid moulded foamed PUR parts up to a size of 500 mm x 1,000 mm and density from 50 – 300 kg/m3

• Integral skin foam moulding to produce moulded foamed PUR parts with a tough textured outer skin over the foam core

• Custom foam properties, including flame resistance, anti-static and many others with special additives - Insert Moulding: Production of moulded foamed PUR parts with plastic inserts, metal brackets and wires moulded directly into the parts for sub-assemblies

- Lamination & Coating: Coating and lamination of a variety of materials onto moulded foamed PUR parts for functional and aesthetic purposes

Applications

Seals & Gaskets

HVAC Seal

Industry

- Automotive

Function

- Sealing, Vibration Absorption

Materials

- Foamed PUR

Headset Earpiece Pad

Industry

- Consumer & Industrial

Function

- Sealing, Noise Insulation

Materials

- Foamed PUR

Housing Parts

Portable Vacuum Casing

Industry

- Consumer & Industrial

Function

- Soft touch and comfort fee, Vibration Absorption

Materials

- Coloured foamed PUR overmould on ABS plastic part

Interface / Support Parts

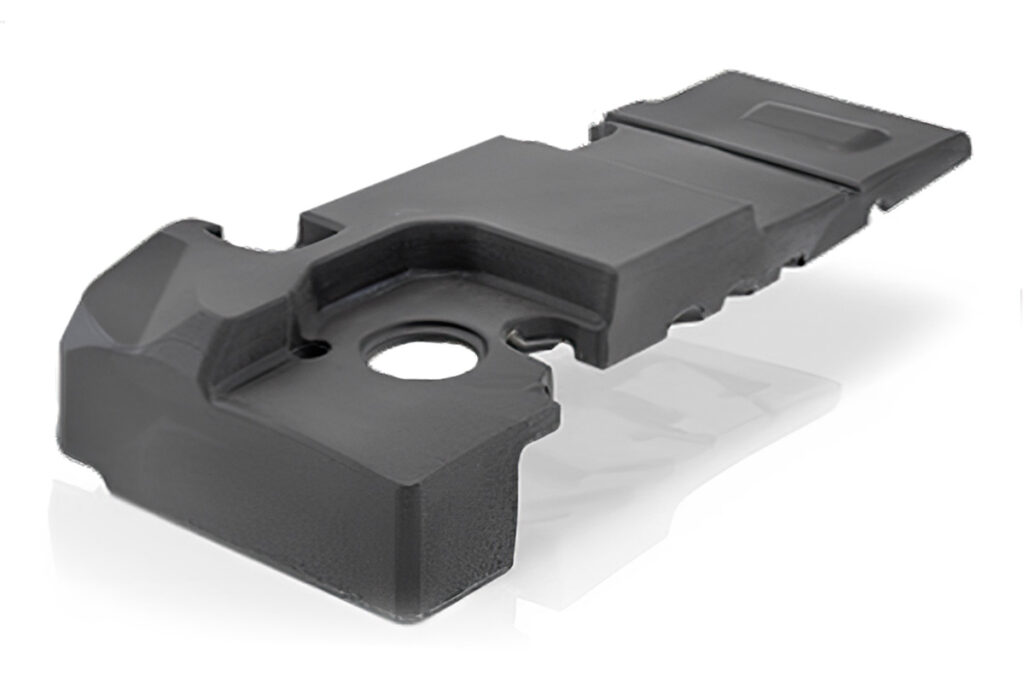

Orbital Sander Pad

Industry

- Automotive

Function

- Interface Part, Vibration Absorption

Materials

- Foamed PUR over mould with PAGF plastic and velcro

Adjustable Table Motor Sleeve

Industry

- Consumer & Industrial

Function

- Support, Vibration & Noise absorption

Materials

- Foamed PUR

Suspension System Parts

Orbital Sander Pad

Industry

- Automotive

Function

- Shock absorption

Materials

- Foamed PUR